9 INDUSTRY INNOVATIONS FROM SUDENGA INDUSTRIES

Work smarter not harder with these nine innovations from Sudenga Industries, a leading manufacturer of grain, feed and seed handling equipment.

Work smarter not harder with these nine innovations from Sudenga Industries, a leading manufacturer of grain, feed and seed handling equipment.

BY GREG VERSTEEG, V.P. Marketing

The term “work smarter… not harder” was coined in the 1930’s by an industrial engineer named Allen F. Morgenstern, the creator of a work simplification program.

The program’s intent was to increase the ability of people to produce more with less effort.

Speaking in Milbank, South Dakota recently, Michael Swanson, Wells Fargo’s chief ag economist, talked about three ways to prosper in farming today.

1. Do more price risk management.

2. Carry less debt.

3. And finally, “Don’t fall for the myths about the impact global population and income growth will have on U.S. agriculture.”

“World population growth doesn’t automatically correlate to an income increase for everyone in U.S. agriculture,” Swanson said. “A key to being profitable in the future is to produce grain, meat and milk more efficiently and economically than your competitors.”

The key is to make the agriculture industry more profitable by working smarter, not harder.

Sudenga Industries’ journey from blacksmith shop to agricultural equipment manufacturer is rooted in the “work smarter, not harder” philosophy. Today, as in the past, the development of “labor saving devices” which can provide an edge in the marketplace for ag producers, continues to be an important pillar on which we base our growth.

Sudenga invests heavily in systems and people who can constantly develop new products to solve problems. This direct investment in our innovation cycle means we are always dreaming up ways for the ag industry to work faster, smarter and better. There have been more than a few imitators of our innovations over the years, but we choose to be complimented by the copies.

Here are 9 examples of our recent product developments:

1) Low-profile conveyors – Sudenga developed the line of low-profile conveyors for modern grain handling applications several decades ago. This conveyor’s versatile, low-profile design requires less structure and less install time, saving money for the installer and customer while still rivalling the throughput of a traditional conveyor system. The applications for this product family are endless, from grain receiving to return conveyors to bin loadouts. The newest low-profile conveyor in the family is the 4019, which handles up to 17,500 bu/hr meaning a 1000 bu grain trailer can be loaded, or unloaded in as little as three and a half minutes.

Read more here https://sudenga.com/our-products/chain-conveyors

2) Shallow double drive over – Utilizing experience only Sudenga has gained from years of low-profile conveyor research and development, Sudenga introduced the Shallow Double Drive Over several years ago. The benefits of this dual inlet, low-profile grain “pit” include less structure and faster installation time than a traditional deep pit conveyor system. End users enjoy faster and more convenient unloading of the grain trailer. Eliminating the need to move the trailer once in place can save as much as four minutes per load during harvest time! Like the low profile conveyors, this system can handle up to 17,500 bu/hr.

Read more here https://sudenga.com/our-products/chain-conveyors/double-drive-over-shallow

3) Bin sweep clean floor kit and self-cleaning end wheel – The combination of our clean floor kit with self-cleaning end wheel turns a traditional power sweep into a grain moving, floor cleaning machine. Floor cleaning results of this attachment rival those of a paddle style sweep, with less cost! The self-cleaning reduction end wheel lasts three times longer than traditional end wheels and leaves significantly less grain along the bin wall. This innovation is standard on all 10” and 12” power sweeps and is an available option on 8” power sweeps. A version of the Clean Sweep kit is also standard on Sudenga commercial “D” series bin sweeps.

4) Removable trough bearings for u-trough power sweeps – Trough mounted hanger bearings provide auger flighting support for less auger chatter and fewer long-term maintenance problems which are often associated with auger vibration in your power sweep. Sudenga’s design allows bearings to be serviced from above with no grain in the bin, or by sliding the underbin flight and bearings out when there is grain on the bin floor. The bearings self-seat. An added benefit of this system is that underbin flightings are in a more manageable 10’ size range.

5) 10,000 bu/hr power sweep for 13” drying floors – Sudenga developed the industry’s first, and only 10,000 bu/hr power sweep that fits in a 13” dryer floor. The 12” UT Power Sweep design saves the extra expense of having to specify taller floor supports, all while offering the highest capacity power sweep unload rate in the industry. This u-trough power sweep incorporates all of the wonderful features and benefits of the 10” u-trough power sweep, but in a 12”, 10,000 bu/hr format.

Read more here https://sudenga.com/our-products/grain-bin-standard/u-trough-power-sweep

6) Above floor collector ring – Mounting the electrical collector ring above the floor in a commercial bin sweep application offers the necessary benefit of permanently wiring your zero entry sweep, but requires less center sump depth. A Sudenga “D” series sweep with an above floor collector ring can be mounted above a center sump that is only 16” in depth meaning concrete floor to tunnel depth is minimized. The patented above floor collector ring design is ideally suited for new construction and retrofit applications.

7) D150/D100 commercial bin sweep – Leading with the auger, Sudenga’s “D” Series commercial sweeps get into the grain pile, aggressively engaging clumped grain and ensuring the sweep advances. This entire sweep raises and lowers itself from the floor automatically ensuring staff can stay out of the bin, not having to adjust common sweep jacks, before engaging the sweep or filling the bin. The “D” Series sweeps offer motorized push tractor or floor track drive advance options while the standard Clean Floor kit leaves less grain behind. A number of innovative zero entry control panels are available as well.

Read more here

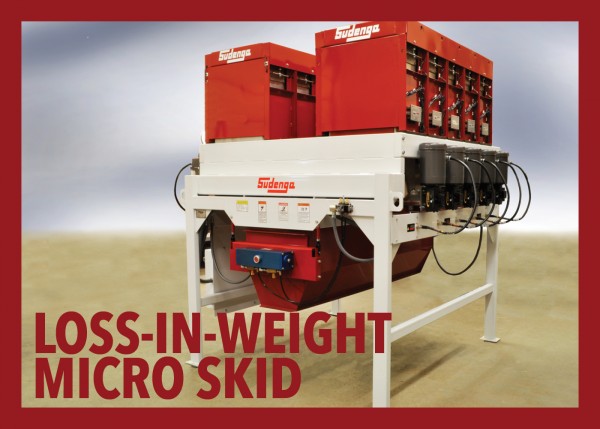

8) Sudenga Industries has designed and installed the feed industry’s first and only line of NTEP lab certified Loss-In-Weight Micro Ingredient Skids for advanced feed manufacturing. With NTEP certification, legal-for-trade, loss-in-weight feed batching is significantly easier to achieve.

Read more here https://sudenga.com/our-products/feed-processing/loss-in-weight-micro-systems

9) Sudenga’s Atlas NXT feed truck design offers the leading unload rate in the industry. Handling up to 8500 lb/min, averaging 7000 lb/min in feed, read more about one customer’s experience with the Atlas here!

Read more here https://sudenga.com/our-products/bulk-feed-trucks-trailers/atlas-nxt-high-capacity-trailers-trucks