- Specifications

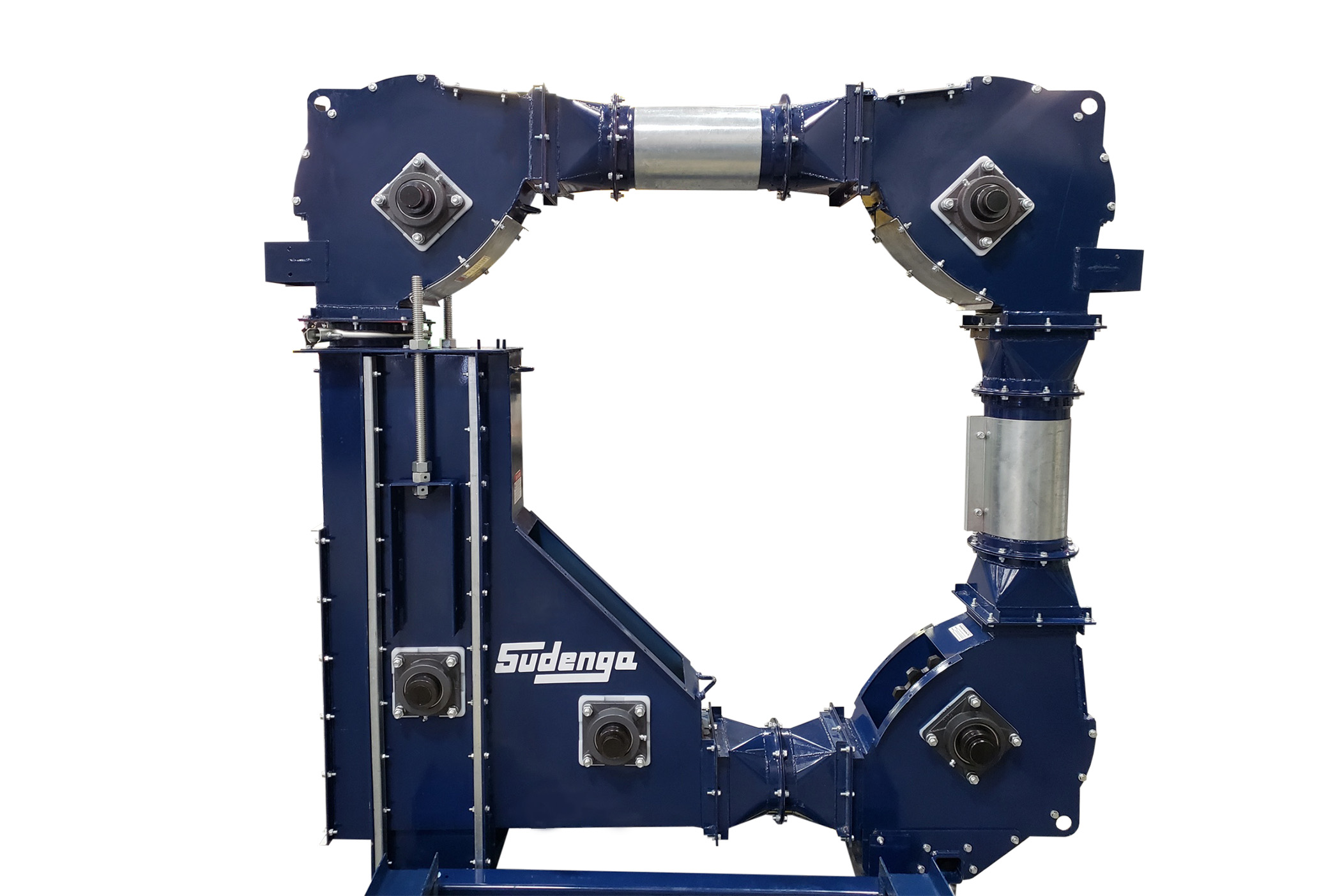

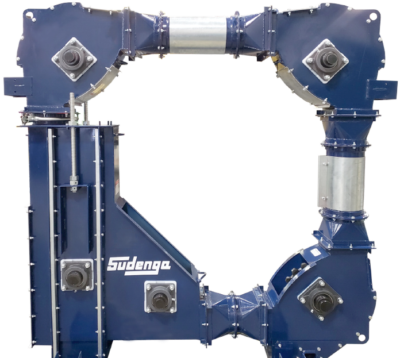

- Photos

- Installations

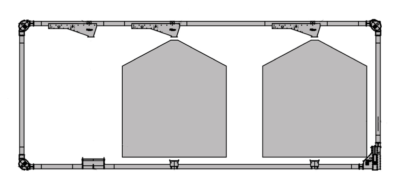

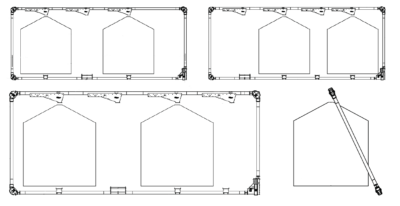

Loop

Standard Features

- Totally modular

- Available in 8”, 10” and 12” diameter systems

- Galvanized outer tubes standard when supplied by Sudenga

- Standard and optional heavier gauge tubes available

- Dodge gear reducers

- Inlet hoppers, grated inlet hoppers, flow-thru bypass inlets, inspection sections, manual and electric intermediate discharges

- Ultra High Molecular Weight (UHMW) paddle keeps grain flowing gently and evenly from inlet to discharge source

Options

- Truss kits, stands, inspection sections

- A complete line of Loop Conveyor tower and catwalk is available.

Specifications

| 8″ Loop | 10″ Loop | 12″ Loop | |

|---|---|---|---|

| Conveying Tube Dimension | 8” diameter (20.3 cm) | 10” diameter (25.4 cm) | 12” diameter (30.5 cm) |

| Max Capacity* | 4,000 BPH (112 TPH*) | 6,000 BPH (169 TPH*) | 10,000 BPH (281 TPH*) |

| Chain Travel | 325 FPM | 325 FPM | 400 FPM |

| Head Shaft RPM | 99 RPM | 88 RPM | 80 RPM |

| Tube Gauge Galvanized | 14 gauge | 12 gauge | 10 gauge |

| Paddle Thickness | ½” | ½” | ½” |

| Corner Shaft Diameter | 2-7/16” | 2-7/16” | 3-7/16” |

| Conveyor Chain | D81XHH | D81XHH | D81XHH |

| Conveyor Sprocket | 15 tooth | 17 tooth | 23 tooth |

*Capacity in TPH using 45# cu. ft. material

Customizable

Versatile closed-loop design for a complete load-in/load out system. Multiple sizes and configurations available for nearly endless customization possibilities.

Hog Feeding Operation near Lismore, MN

Check out this Lismore, MN farm site featuring a painted feed leg, micro skid, weigh hopper, mixer, tote bag system, and loop system.

Read More

Farm Feed Mill Setup near Little Rock, IA

Check out this farmer-operated feed mill setup. From a hammermill to a horizontal mixer to Sudenga’s feed loop conveyor system, this site has it all.

Read More