- Specifications

- Photos

- Installations

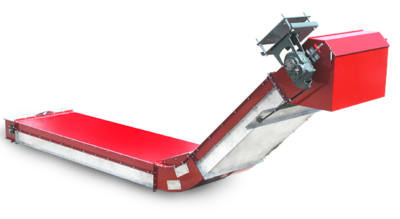

Overview

Originally developed to feed bucket elevators from shallow drive over pits, thousands of applications later these units can be found loading out to semi-trailers or returning grain to the leg from a low clearance loadout. Interchangeable hopper gratings and bridge sections allow for custom intake configurations.

- Eliminate water problems common in pit installations. The 16” (2610), 19” (4012), or 26” (4019) deep trench is open at both ends for drainage.

- Unloading rates from 3000 to 17,500 BPH.

- Modular design for variable lengths and discharge heights.

- Cover and grate sections for the “drive over”

area are available in various lengths to accommodate various width trenches.

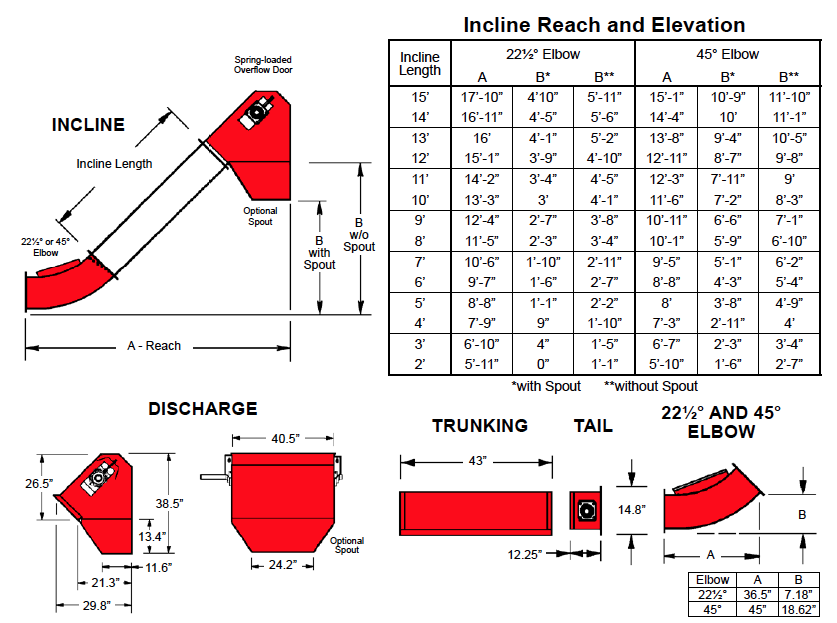

Model 4019

STANDARD FEATURES

- 12,500, 15,000 and 17,500 BPH unloading rates

- 10 ga. galv. trunking housing with 7 ga. dividers

- 22.5° & 45° elbow and head sections

- 14” x 14” and 16” x 16” discharge reducer

- Double 81XHH chain with polyethylene paddles

- Outboard mounted pillow block bearings with dust seals

- 21” deck height

- Modular sections available in 1’, 2’, 3’, 5’ and 10’ lengths.

- Conveyors require a trough 48” wide and 26” deep. Trench can be left open at ends for drainage.

- Combination heavy gauge galvanized and painted trunking sections.

- Painted head, curves and tail sections. (Standard paint color is blue)

- Commercial duty shaft mount gear reducer

- Heavy duty head and tail sprockets on turned ground and polished shafts

- Head mounted inspection/overflow panel

- Intake grates and solid drive over covers can be repositioned for full width, center or side discharge situations. Grates and bridges available in 24” x 32”, 12” x 48”, 24” x 48”.

- Gated grates and flow restrictor pans available

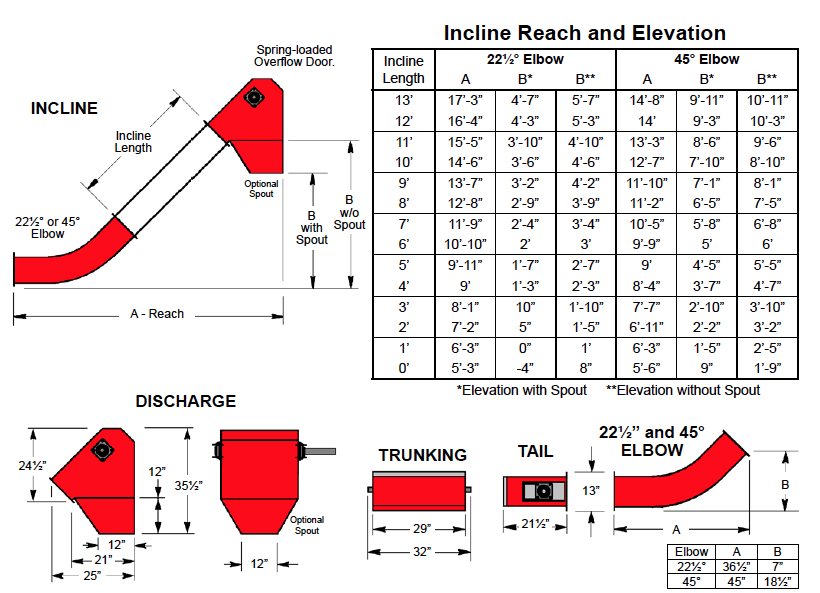

Model 4012

STANDARD FEATURES

- 5000, 7000 and 10,000 BPH unloading rates

- 10 ga. galv. trunking housing

- 22.5°, 45° & 60° elbow and head sections

- Discharge opening 21” x 40” or 12” x 24” reducer

- Double 81X chain with polyethylene paddles

- 14” deck height

- Modular sections available in 1’, 2’, 5’ and 10’ lengths.

- Conveyors require a trough 48” wide and 19” deep. Trench can be left open at ends for drainage.

- Combination heavy gauge galvanized and painted trunking sections.

- Painted head, curves and tail sections. (Standard paint color is blue)

- Commercial duty shaft mount gear reducer

- Heavy duty head and tail sprockets on turned ground and polished shafts

- Head mounted inspection/overflow panel

- Intake grates and solid drive over covers can be repositioned for full width, center or side discharge situations. Grates and bridges available in 24” x 32”, 12” x 48”, 24” x 48”.

- Gated grates and flow restrictor pans available

Model 2610

STANDARD FEATURES

- 3000, 5000 and 7000 BPH unloading rates

- 10 ga. galv. trunking housing

- 22.5°, 45° & 60° elbow and head sections

- 12” x 12” discharge reducer

- Single or double 81X chain configurations with polyethylene paddles

- 11.5” deck height

- Modular sections available in 1’, 2’, 5’ and 10’ lengths.

- Conveyors require a trough 32” wide and 16” deep. Trench can be left open at ends for drainage.

- Combination heavy gauge galvanized and painted trunking sections.

- Painted head, curves and tail sections. (Standard paint color is blue)

- Commercial duty shaft mount gear reducer

- Heavy duty head and tail sprockets on turned ground and polished shafts

- Head mounted inspection/overflow panel

- Intake grates and solid drive over covers can be repositioned for full width, center or side discharge situations. Grates and bridges available in 24” x 32”, 12” x 48”, 24” x 48”.

- Gated grates and flow restrictor pans available

Low-Profile Chain Conveyor near Melvin, TX

Sudenga’s range of low-profile chain conveyors provides an optimal solution for establishing an unloading setup with minimal requirements for dirt and concrete work.

Read More

Low-profile pit near Dimmitt, TX

This site near Dimmitt, TX features a low-profile receiving pit. Sudenga’s 2610 chain conveyor is a great option in areas with water issues.

Read More

Farm Site near Warren, MN

This farm site near Warren, MN features two double-run chain conveyors, a bucket elevator system, and a low-profile receiving pit.

Read More

Farm Site near Adair, IA

Check out this Adair, IA farm site featuring two Double Barrels and low-profile chain conveyor receiving pit from Sudenga.

Read More

Farm Site near Springfield, OH

Check out this Springfield, OH farm site featuring a Double Barrel and low-profile chain conveyor from Sudenga.

Read More

Farm Site near Jasper, MN

Check out this Jasper, MN farm site featuring a Hi-Cap 24 bucket elevator and low-profile chain conveyor from Sudenga.

Read More